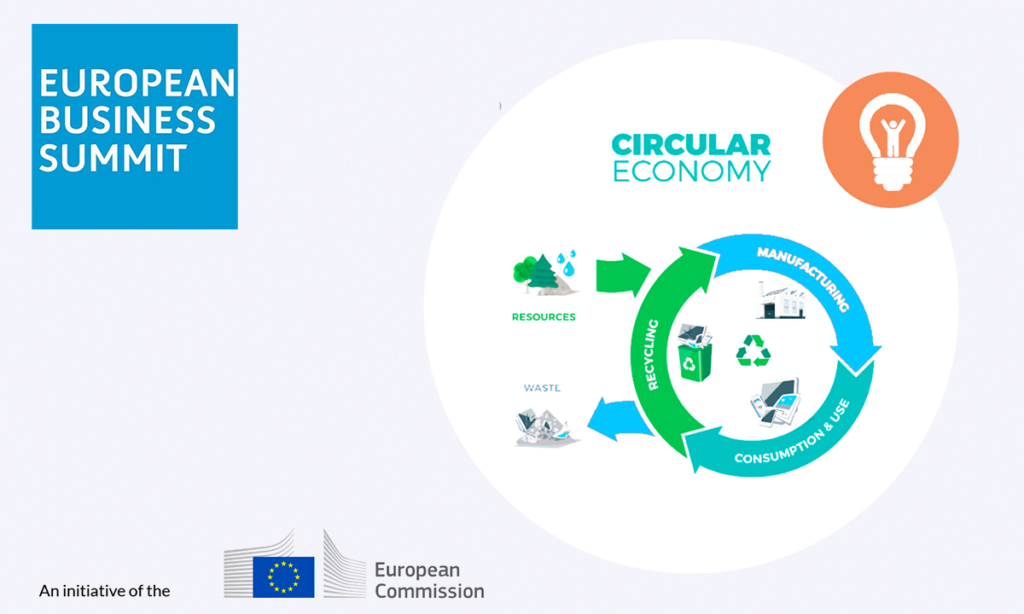

Expert panel: Circular Economy

Business4Change Hackathon

Join the Hackathon to watch the pitches and closing ceremony!

Business4Change is a 4-day hackathon contest, organised to ‘hack’ or solve issues businesses are facing in their transition to the circular economy. The hackathon emphasizes the potential of social innovation and the role of new business models in the circular economy. Business4Change is an initiative of the European Commission and will take place on 11-16 November 2020 online in tandem with the European Business Summit.

Over the course of 4 days, different teams will compete against each other to come up with innovative and creative solutions to solve a practical challenge related to the circular economy. The challenges are selected in collaboration with challenge owners and experts representing companies, associations, and NGOs. Leading up to the hackathon, selected experts will share their knowledge on the circular economy with the participants. On the second day, teams will pitch their ideas via a live broadcast and compete to win mentorship opportunities from Suez, AbInBev and Vinventions!

Challenge 1

The Challenge: How to reduce the supply chain cost of waste plastics packaging? Help SUEZ reduce the supply chain cost of waste plastics packaging!

Let’s talk about plastics! The amount of plastic produced in Europe today is 50 times what it was 50 years ago (with over 8 billion tons of plastic being produced by industries since 1950 alone). To complicate this even further, each year, the transport of hundreds of millions of tons of waste has an immense impact on society. Just to give you a perspective, this accounts for 30% of the greenhouse gas emissions (GHG) generated in waste management (which is the equivalent of several million tons of CO2). SUEZ processes more than 400,00 tons of plastics each year to produce 100,000 tons of recycled polymers. The challenge is that the characteristic of plastic packaging waste is its very low density generating high logistic costs between the point of collection until the gate of the reprocessing plant (about 50 % of the total recycling costs). We are looking for innovative ideas to reduce logistics costs across the supply chain.

Challenge 2

The Challenge: Sustainable business models for the collection and sorting of beverage closures.

Finding recycling solutions for beverage closures (wine corks, steel/aluminum bottle caps). Belgian-based Vinventions, one of the most innovative sustainable wine closure companies, has teamed up with global drinks brand Ab InBev to develop a challenge for our teams which looks at a crucial issue in the circular economy: What to do with small items that have limited value for the consumer once past its usage and where current recycling systems are inadequate?

A beverage closure is simply the method used to seal the drink container during production. In the context of this challenge, we are talking about two specific types of closures:

• Wine Corks

• Steel Bottle Caps

At the moment these products are not properly recycled, even though it is possible to do so. A first challenge arises at the collection stage: there is no specific scheme for collecting those products (in a dedicated bag, or through a deposit return system like bottles and cans). Once in the sorting centre, wine corks cannot be separated from other materials (like glass, aluminum, steel and plastic containers) through the use of machines. As a result, the majority of wine corks are burnt in an incinerator or end up going to landfill. Due to their small size, collected steel/aluminum caps fall through the screeners and are overlooked for recovery.

In an effort to avoid pollution from potentially recyclable materials, we need innovative ideas! We are looking for zero-cost solutions at the collection and sorting stages. Ideas for upcycling those products are also welcome